- Home

- Products

- Glass Packaging

- Glass Containers for Food

- Borosilicate Glass

- Borosilicate Glassware

- Custom Borosilicate Glass

- Borosilicate Glass Products

- Borosilicate Glass Kitchenware

- Borosilicate Glass Cookware

- Borosilicate Glass Salad Bowls

- Borosilicate Glass Measuring Cup

- Borosilicate Glass Containers

- Borosilicate Glass Storage Containers

- Borosilicate Glass Lunch Box

- Borosilicate Glass Baking Dish

- Borosilicate Glass Storage Jar

- Glass Lunch Box

- Oil Spray Bottle

- Glass Meal Prep Containers

- Divided Glass Container

- Stainless Steel Bento Box

- Dessert Container

- Glass Fruit Bowls

- Glass Baking Dish

- Glass Spice Jars

- Glass Olive Oil Bottles

- Glass Mason Jars

- Meal Prep Containers

- Glass Food Storage Containers

- Glass Honey Jars

- Glass Pickle Jars

- Yoghurt Glass Jars

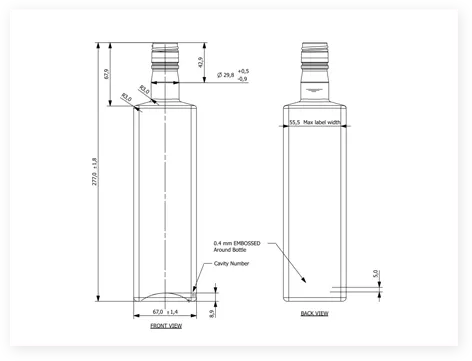

- Glass Bottles for Beverage

- Glass Packaging for Liquor

- Cosmetic Glass

- Cosmetic Packaging

- Perfume Bottle

- Perfume Bottle Cap

- Cosmetic Glass Jars

- Perfume Bottles

- Perfume Sample Bottles

- Perfume Oil Bottles

- Dropper Bottles

- Roll On Bottles

- Attar Bottle

- Portable Perfume Bottles

- Perfume Glass Bottles

- Fine Mist Perfume Atomizer

- Empty Car Diffuser Bottles

- Diffuser Bottles

- Lotion Bottle

- Boston Round Bottles

- Nail Polish Bottles

- Glass Candle Jars

- Services

- About FEEMIO

- Partnerships

- Contact

- Blog